These standards are comparable to what is necessary of the pharmaceutical industry for products which are ingested into the body.

Strategies that may be made use of to manage the routes and ways in which contamination unfold are as assorted as the contamination options on their own. They involve:

synthetic medication manufacturing, about fifty five p.c in the cleanroom sector profits currently will involve biopharmaceutical services.

To make sure that your pharmaceutical cleanroom is thoroughly compliant Along with the rules and as productive as feasible from the utilization of ideal engineering, get in contact with our experts at Blue Thunder Systems now.

The exam assesses the integrity of boundaries and containment techniques to stop the escape of contaminants, guaranteeing the safety of staff and also the encompassing environment.

Clean rooms have precise requirements that have to be achieved to maintain the desired standard of cleanliness. These requirements is often divided into a few categories: staff requirements, environmental requirements, and gear requirements.

We also use third-social gathering cookies that assistance us analyze and understand how you use this Web site. These cookies is going to be stored with your browser only together with your consent. You even have the option to decide-out of such cookies. But opting away from Some cookies may possibly affect your searching encounter.

Practical cookies support to conduct particular functionalities like sharing the articles of the web site on social media marketing platforms, obtain feedbacks, along with other 3rd-occasion options. Efficiency Efficiency

Employing HEPA filters to circumvent contaminants coming into get more info the cleanroom Using the air provide. This doesn't, nevertheless, address unfiltered air passing by way of a broken filter.

In earlier posting We now have talked over in specifics about what exactly is therapeutic index and what's meant by narrow therapeutic index drug . Her...

The next post provides a fundamental overview of widespread inquiries referring to the classification of a cleanroom. The purpose of this guideline is to supply design and building solutions for cleanrooms housing bio-pharmaceutical processes.

Airflow features Enjoy a big part in keeping the expected air good quality within the cleanroom.

These methods read more are diligently picked out to offer a comprehensive photograph on the cleanliness degree inside the sterile producing surroundings. The key sampling solutions include:

While in the foodstuff industry, medical know-how as well as the pharmaceutical industry, solution security and buyer security are becoming significantly essential.

Scott Baio Then & Now!

Scott Baio Then & Now! Patrick Renna Then & Now!

Patrick Renna Then & Now! Romeo Miller Then & Now!

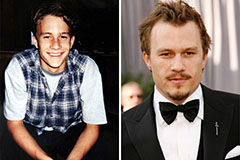

Romeo Miller Then & Now! Heath Ledger Then & Now!

Heath Ledger Then & Now! Nicki Minaj Then & Now!

Nicki Minaj Then & Now!